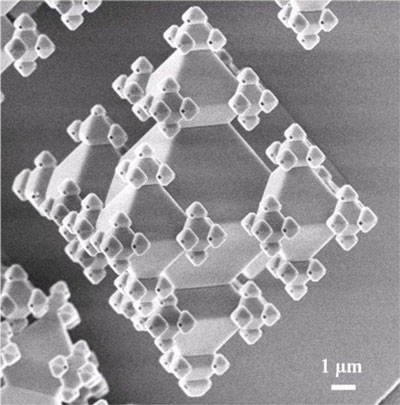

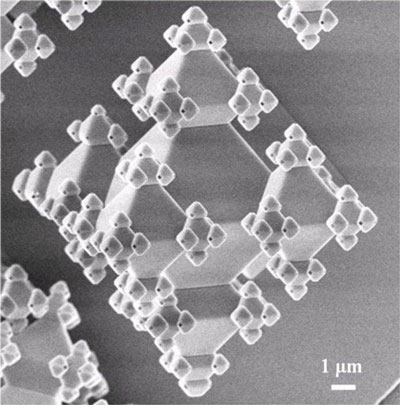

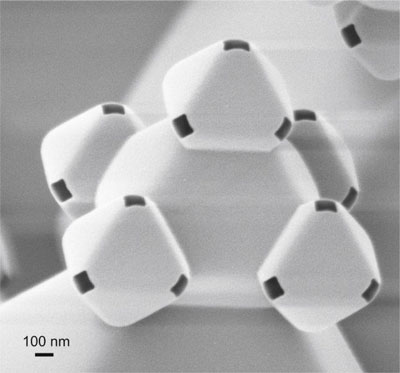

OverviewSelf-similar patterns are frequently observed in Nature. Their reproduction is possible on a length scale102–105nm with lithographic methods, but seems impossible on the nanometer length scale. It is shown that this goal may be achieved via a multiplicative variant of the multi-spacer patterning technology, in this way permitting the controlled preparation of fractal surfaces. |

|

Technical Details

To be able to create the repeated 3D structure, the scientists developed a technique called ‘corner lithography’’. At first, a pyramid form is etched in silicon. The next step is applying a layer of silicon nitride on the pyramid. After removing this subsequently, a tiny bit of nitride stays in the corner of the pyramid, functioning as a ‘stop’. When this is removed, the silicon underneath is etched through the tiny hole. Automatically, a structure is formed alongside the silicon crystal plane. This is the first octahedron, formed by ‘auto alignment’. The process is repeated with a new layer of silicon nitride. The size of the new octahedra is determined by the etch period. In this case, every octahedron in the next step is half the size of the previous one. The advantage of corner lithography is its relative simplicity. No advanced technology is needed to create each individual nano pore. On the contrary: in just four steps thousands of fractals, each having 625 tiny holes can be processed on a wafer, in parallel. More than four steps is also possible, but this places higher demands on the etching process.

|

|